Storage Tank Floor Inspection – The Critical Zone in Storage Tanks

In our previous blogs, we explained in detail how we conduct in-service tank bottom floor inspections. One limitation of storage tank bottom inspection robots is that it is impractical for them to get data from the lower corners, ie. immediately near the tank walls.

In actuality, RUVI Oildiver can be configured to reach to and get signal from even dead corners. However, the main issue for in-service inspections of the critical zone is the heavy sludge that is typically present in such locations. This sludge makes it difficult to conduct healthy thickness readings from the corners. On the other hand, corners are important locations that need to be inspected. In fact, due to the extra stress that occurs in these corners, they are classified by API 653 as “critical zones”. These critical zones in storage tank floors made it necessary for us to develop an additional solution for their inspection.

We believe in a holistic approach in robotic inspection. The ultimate goal is to inspect the whole tank robotically, minimizing human error, inspection time, environmental impact and OHS risks. Since our robots specialize in providing high quality solutions for specific industry pain points, different problems in industry are best challenged by different robots. If one robot has a limitation in its scope, this limitation can be remedied by another supplementary robot.

This is our approach to the critical zone inspection in storage tanks. While RUVI Oildiver inspects the general tank floor, the best quality for critical zone inspection can be obtained by a robot fully dedicated for this task. For the tanks in which critical zones are inaccessible by RUVI Oildiver, we have developed PAars Annular Ring Inspection Robot, designed specifically to inspect critical zones in storage tank floors. In this post, we aim to provide information about critical zone inspections and our robotic solution PAars.

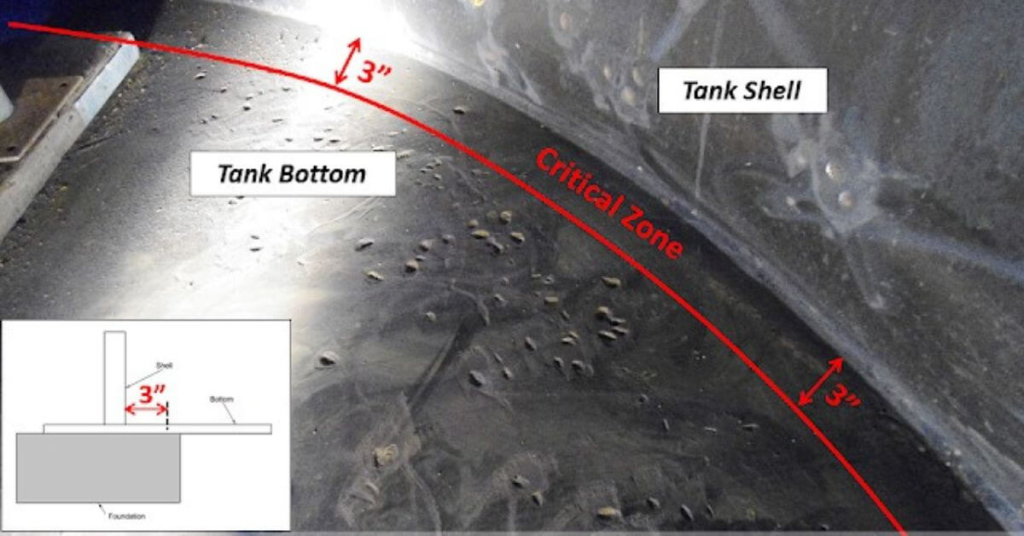

Where is The Critical Zone in a Storage Tank?

Critical zones are defined as the lower corners of the storage tanks, 3 inches (7.6 cm) of inside edge of the shell. Critical zones are not only under the weight of the shell, but they are also prone to sludge build up. This area also contains the weld between tank shell and tank bottom. Due to these issues, critical zones are typically built with a higher thickness. The unique situation of the critical zones of storage tanks makes their inspection more crucial. Higher stress means higher probability of defects occurring and a general higher rate of loss of thickness.

How to Inspect the Critical Zone?

In conventional tank inspections, since the tank is emptied and the bottom is cleaned prior to inspection, critical zones can be inspected just like the rest of the tank floor. However, in service robotic inspection of the storage tank bottom floors has a weak point for the critical zone inspection in storage tanks.

Our RUVI Oildiver robot has 32 UT probes, collecting comprehensive data from the tank floor. If the critical zone is relatively clean, ie. has low levels of sludge, RUVI Oildiver’s probes can be configured before operation to obtain critical zone data.

However, the critical zone is most of the time not clean and has significant sludge build-up. This makes it difficult for the robot to get near the critical zone for inspection and also makes it difficult to obtain accurate UT measurement data due to sludge interference. Due to this, we have presented our dedicated robot PAars to inspect the critical zone.

Does Inspection Report Quality Matter?

Above all else, inspection aims to collect accurate data. Accurate data can be used to gauge the estimated lifetimes of industrial assets, predict when, where and how failures are going to occur and prepare future maintenance roadmaps. Our robotic inspection solutions provide abundant, accurate, repeatable data very quickly.

However, just as important is a high quality report that is processed by expert personnel that provide valuable insights. In the age of big data that we live in, data processing is nearly as important data gathering. Another aspect of high quality reports is that they provide compliance. AIS Field’s in-service robotic inspection solutions for storage tanks, RUVI Oildiver and PAars Annular Inspection Robot, provide reports for storage tanks are fully compliant with the mandatory API 653 regulation. AIS Field’s NDT Level II and Level III experts prepare comprehensive reports from our robotically obtained data, to provide valuable insight to our customers as well as to ensure their compliance.

How AIS Field can Help You?

Our critical zone inspection robot, PAars Annular Ring Inspection Robot, is specifically designed to solve the issue of critical zone inspection is storage tanks. Unlike RUVI Oildiver, PAars does not need to dive the tank; it can inspect from the outside. It is an automated scanner attached to the tank shell wall.

PAars is equipped with the integration of ultrasonic phased array and 0-degree. Once attached to the tank bottom edge from the outside, PAars is able to detect plate defects from the tank interior, up to 1 meter away from the tank shell. It is able to characterize defects up to 40cm away from the shell. If we remember that the critical zone is defined as 7.62 cm away from the tank shell, it can be asserted that PAars provides a definitive solution for the critical zone inspections for storage tanks.

PAars service can be provided standalone, but it is typically offered as supplementary with our RUVI Oildiver to provide a full picture tank bottom inspection.