Enhancing Integrity Management through EEMUA 247-Based Robotic Inspection Analytics

Traditional tank inspection requires storage tanks to be taken out of service. Depending on the tank size, this process can take several months, resulting in substantial costs and downtime for the tank owners. Additionally, human entry into confined and hazardous spaces poses significant health and safety risks, along with emissions and environmental waste. Therefore, in storage tank integrity management, the ability to inspect tank floors without taking them out of service is a game-changing approach. Driven by operational efficiency, safety concerns and the need to reduce emissions, in-service robotic inspections are rapidly becoming an industry standard. However, due to inherent challenges in tank geometry, such as attachments, columns, and other obstructions, or sludge accumulation at the bottom of the oil tank, 100% inspection coverage is not always possible with robots. As a result, there is a need to create maximum value even without full surface coverage.

As one can imagine, partial inspection coverage introduces new challenges in data interpretation and risk evaluation. That is where EEMUA Publication 247 (2025 Edition): Statistical Analysis of In-Service Tank Floor Inspections comes in. The recently published EEMUA standard offers a comprehensive statistical framework for planning and evaluating partial-coverage robotic tank floor inspections. This was a significant and timely development for the robotic storage tank inspection industry.

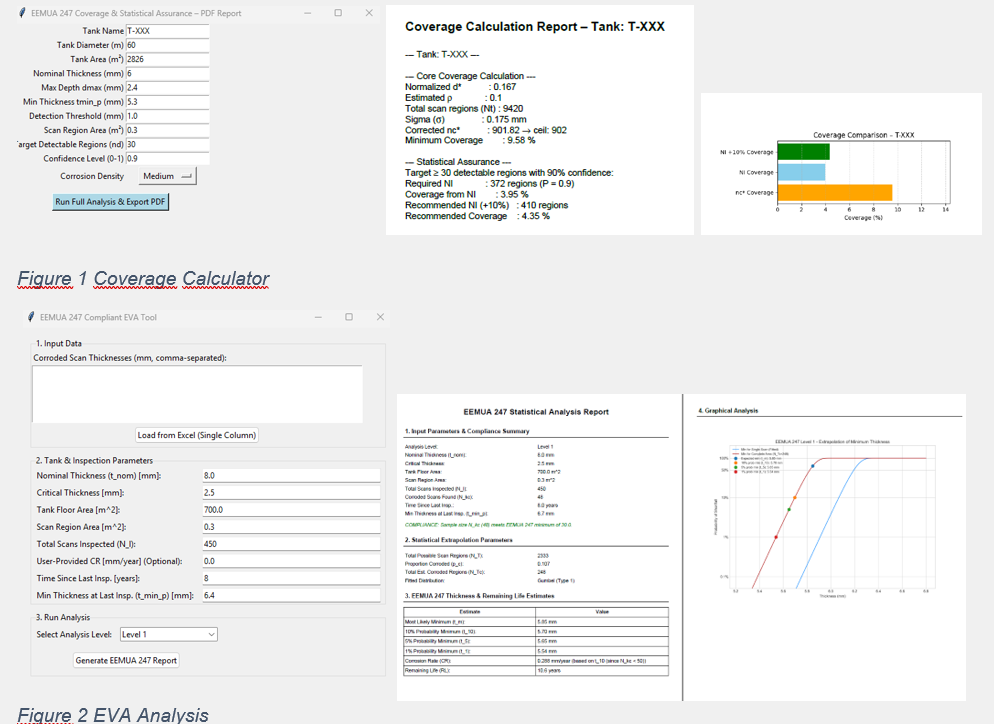

At AIS Field, we provide oil tank inspections using our ATEX Zone 0 certified robotic system, RUVI OilDiver. Leveraging our experience and expertise, and building on the EEMUA 247 standard, we have developed a proprietary software tool that automates both the planning and statistical evaluation processes described in the publication. Additionally, following partial coverage inspections, evaluating the remaining life of the tank requires Extreme Value Analysis (EVA), as outlined in the API 575 standard. We have also developed a tool that automatically performs EVA following our tank inspections. In this article, we will introduce the key features of our software and the value it brings to tank operators, inspection providers and integrity engineers.

Understanding EEMUA 247

As mentioned, due to the nature of online robotic inspections, 100% of floor coverage is not always possible. EEMUA 247 provides detailed guidance on the optimum coverage and statistical analysis of in-service tank floor inspections using robotic tools. It categorizes inspections into three main types based on the presence and detectability of corrosion.

- Type A: Where no significant wall loss is expected.

- Type B: Where measurable wall loss is anticipated and statistical extrapolation is required.

- Type C: Where wall loss may be severe but isolated (requiring tailored justification).

The standard emphasizes the importance of:

- Corrosion risk assessment (CRA)

- Determination of corrosion density and spatial homogeneity

- Minimum inspection coverage calculations based on detection threshold and corrosion depth

- Use of Extreme Value Analysis (EVA), particularly Gumbel or Generalized Extreme Value (GEV) distributions, to predict the probability of critical wall loss in uninspected areas.

About Our EEMUA 247-Based Software Tool

Our RUVI OilDiver Analytics Software Tool transforms the EEMUA 247 methodology into an intuitive, interactive platform for inspection planning and evaluation. Key capabilities include:

- Coverage Calculation

- Distribution Fitting and EVA Module

- CRA Support and Density Classification

- Automated Reporting and Visualization

You can see both our coverage calculator and EVA analysis interfaces in the screenshots above.

Why This Matters

In-service robotic inspections, by nature, cannot achieve 100% floor coverage, especially in large diameter tanks with numerous internal obstacles. Our approach, built on the EEMUA 247 and API 575 standards, enables asset owners to overcome this limitation by applying robust statistical analysis to make confident integrity decisions, even when only a portion of the floor is inspected.

In simpler terms, depending on the tank’s geometry and inspection history, we use the EEMUA 247 guidelines to calculate the minimum inspection coverage required for reliable integrity decisions. Once our robot covers that targeted portion, we perform Extreme Value Analysis (EVA) to accurately assess the tank’s remaining life and overall integrity condition. While RUVI OilDiver operates inside the tank, our inspection team also conducts a full API 653 inspection, allowing us to deliver a complete inspection package to our customers. This combined approach adds significant value to our clients’ operations.

By aligning fully with EEMUA 247, the tool ensures consistency, traceability and defensibility of the inspection strategy. Therse are critical elements in regulatory compliance and internal risk management processes.

Conclusion

Robotic inspection technology has advanced rapidly, but the real power lies in planning the inspection and interpreting the data correctly. By codifying the principles of EEMUA 247 and API 575 into our internal procedures and also a software solution, we provide tank operators and service providers with the analytical edge they need to make data-driven integrity decisions.

To learn more about our solutions, feel free to get in touch with our team.