Importance of Compliance With Standards and Risk-Based Evaluation

Importance of Compliance: Compliance is one of the most important aspects of industrial safe practices for a number of reasons;

- Avoiding Legal Repercussions: Failure to comply with the standards may result in fines and sanctions as well as legal fees. Compliant firms will avoid all that.

- Safety: Standards exist for a reason. Compliance with standards will minimize the risk of accidents, failures, leakages etc. for a safe and sound operation.

- Operational Efficiency: Ensuring that every piece of equipment is working as intended is crucial for efficient operation. Any small flaw can cause catastrophic failure but also just a small flaw in the operation may cause it to run inefficiently, costing significant money in the long run.

- Reputation: Companies that have a perfect record of ensuring or even exceeding standards will be regarded more highly by all stakeholders, including customers and investors.

- Environmental Protection: Industries that handle hazardous materials, such as the petrochemical industry, can significantly harm the environment if they do not adopt safe practices. Compliance ensures that all the hazardous materials are handled safely.

Using A New Method for Ensuring Compliance: RUVI OilDiver

While compliance with conventional methods brings those benefits, using a new cutting-edge method for ensuring compliance brings even further benefits. For example, inspections with our RUVI OilDiver robotic tank inspection system for your API 653 compliant fuel tank inspections will go further and beyond for all those five purposes;

- Our in-service RUVI OilDiver API 653 robotic inspection takes merely one-tenth of the time required for conventional out-of-service API 653 inspections take, which means we can inspect ten tanks in the time it normally takes to inspect one. This means you will always be up to date with your inspections.

- Robotic inspection has the sizeable advantage of avoiding human error during inspections, resulting in healthier data. Moreover, it removes the significant safety risks that occur during the inspection, such as working at heights or in confined spaces, as well as the exposure to toxic materials.

- Our in-service RUVI OilDiver API 653 robotic inspection allows the operation to carry on as usual during the inspection process, saving precious operating hours.

- Utilizing the latest technologies does wonders for a company’s public image. Transforming API 653 inspections from conventional out-of-service manual method to the safer, greener and more efficient robotic inspection method will bring immense prestige for a company.

- While helpful in preventing long-term environmental harm, during the inspection, conventional API 653 tank inspections cause 5-20 tons of emissions of CO2e/100m ⌀ tank as well as a large amount of toxic sludge from the tank bottom. Leaving the tank contents completely intact, our in-service RUVI OilDiver robotic inspection method avoids causing any environmental impact.

Is RUVI OilDiver Fully Compliant?

Due to its many benefits, in-service robotic fuel tank inspections are becoming widespread in the world. This led to the regulators including it as a compliant method in standards and regulations. Thanks to robotic inspection, Risk Based Assessment (RBI) can now be performed with high quality recorded digital data without taking a tank out of service. The method is included in the internationally recognized EEMUA 159 and API 653 standards.

Due to the obstructions in the tanks, 100% inspection of the tank bottoms is not possible in most applications. For this reason, statistical tools are used to predict the general situation with the scan data in a limited area. The most accepted and widely used of these tools is the Extreme Value Analysis (EVA) method. In-service robotic inspection and the EVA statistical method have gained industrial acceptance in managing tank integrity.

Extreme Value Analysis

Using the EVA statistical tool with homogeneously distributed inspection data from the tank bottom, reliable information about the minimum remaining thickness of the tank bottom plates and the integrity of the tank is obtained.

The EVA statistical method is recognized in API 575 (paragraph 8.4.4.). According to the standard, the EVA method can be used for remaining life analysis if data is collected homogeneously from at least 0.2% to 10% of the tank. If thickness values are found to be sufficient, customers can extend their maintenance period by 10 years as per API 653, without ever taking their tank out of service.

It is widely accepted that there is no measurable difference in determining the remaining life for tank bottom inspection if the data collected is homogeneous across tank bottom plates. The results of field tests and more than 8 independently monitored validation studies show that sampling data from the tank bottom can provide satisfactory results (1).

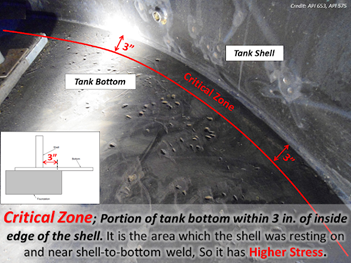

API 653 Critical Zones

Per API 653, the portion of tank bottom 3 inches of inside edge of the shell is designated as critical zone. Sometimes, bottom inspection robots will have difficulties reaching this area.

AIS Field provides another robotic solution for the critical zone. With our Paars Annular Ring Inspection Robot we can inspect tank critical zones. In addition to providing the finishing touch to our robotic in-service tank bottom inspection robot RUVI Oildiver, PAars can also be used stand-alone, as a low-cost and rapid critical zone inspection solution.

(1) Silverman, E., Bass, R., Furillo, F., and Wolf, A., “In-Service Oil Tank Cleaning and Inspection System: Results of Eight Independent Validations,” ASNT Proceedings, Fall Conference, pp. 87-95, November 2000.