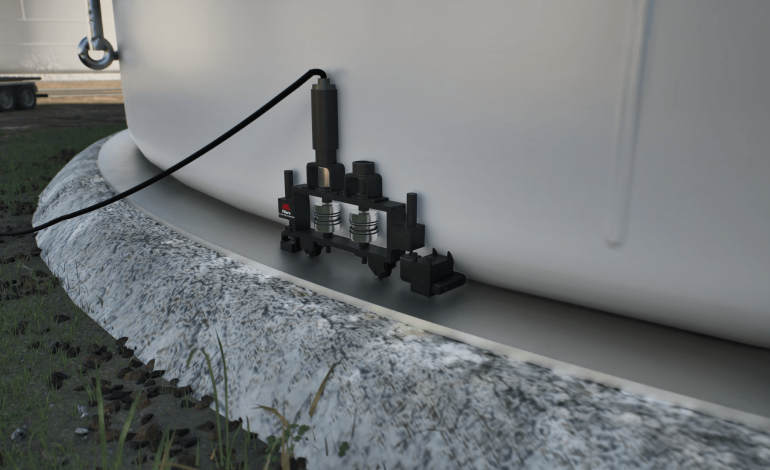

This automated system conducts inspections of the annular ring, a crucial area at the bottom of above-ground storage tanks. Leveraging PAUT technology, it performs external inspections (from outside the tank), with a detection capability of up to 1 meter.

This innovative magnetic crawler provides visual inspection and corrosion mapping for industrial boilers, complemented by a laser profiler. Although it’s primarily designed for boilers, the system can adapt to any magnetic surface requiring inspection with restricted access.

RUVI OilDiver is an ATEX-certified robotic system for online storage tank floor inspection in an explosive environment. With the help of the ultrasonic inspection module on the system, tank floor thickness measurement and corrosion mapping can be achieved according to API 653.

Our robotic solution revolutionizes the cleaning process by eliminating the need for draining water tanks for maintenance—a process that is both costly and risky. We provide the ability to clean and inspect fire water tanks without interrupting the continuous operation.

This underwater drone, equipped with an ultrasonic unit, enables visual inspections and thickness measurements in marine environments and water tanks. It significantly reduces the cost and duration of tank maintenance processes and eliminates the need for divers, thereby HSE standards.